PRODUCTIVE PROCESS

01

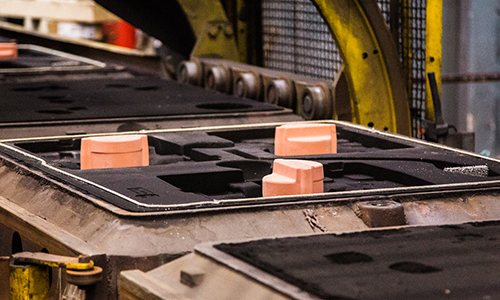

FOUNDRYING

DURITCASTproduces castings using both manual molding with chemical sand and automatic molding with green sand. We produce steel and iron castings from small to medium series.

Moulding

• 1 OMEGA chemical sand molding line, boxes up to 3500×3500; and weights from 150 to 6,000 kg

• 1 semi-automatic chemical sand molding line, boxes 1600x1300x400/400, and weights from 5 to 250 kg

Finishing

• 1 shot blasting machine for castings

• 1 conventional finishing line for parts up to 150 kg

• 1 conventional finishing line for parts up to 6,000 kg

• 1 conventional parts finishing line

• 1 BARINDER automatic deburring machine

Melting

• 1 INSERTEC furnace with a capacity of 2 tons

• 1 INSERTEC furnace with 1 ton capacity

• Production capacity of 11,000 tons per year

Machining

• 1 BICOR machine with three stations and a capacity of 22 liters

• 1 ROPER machine with a capacity of 6.5 liters

Heat treatment

• Normalization

• Stress relieving

• Annealing

Welding

Painting

02

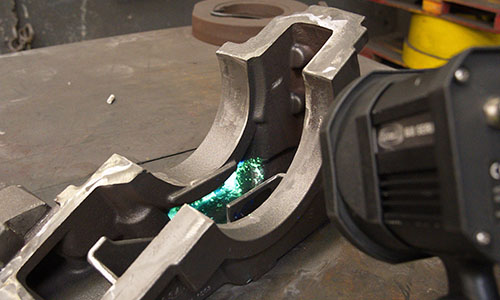

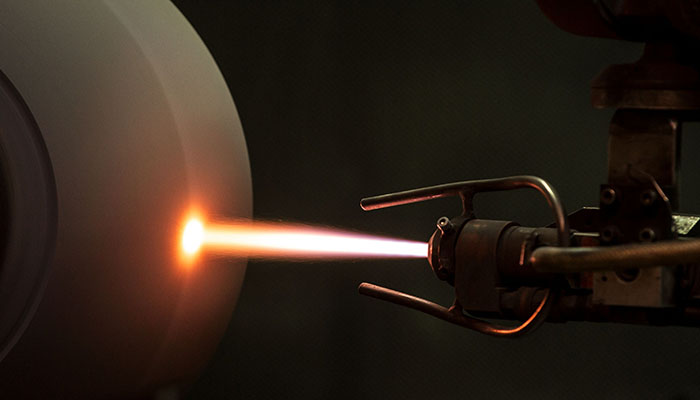

SURFACE TREATMENT

Through DURITCOATINGS, DURITCAST offers its customers high-tech coatings for industrial applications.

DURITCOATINGS is a dynamic company with a strong commitment to R&D, which also adds an after-sales service to its offer.

It offers solutions such as high-speed thermal projection (Plasma, HVOF, EAWS) and physical vapor coatings (PVD, PA-CVD).

03

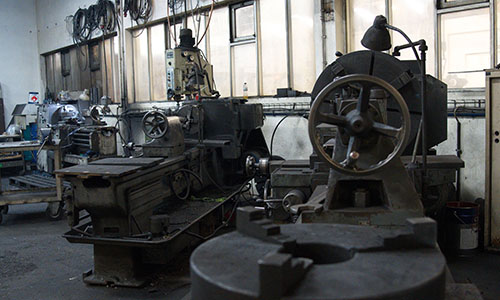

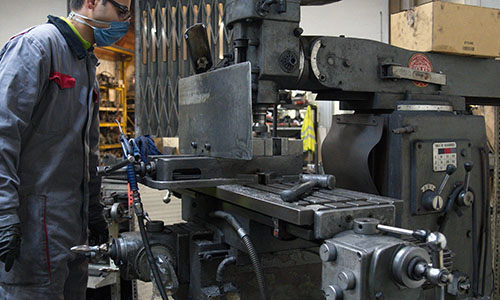

MACHINERY

– 1 Barinder grinding machine

– 1 Milling machine

– 3 Lathes

Extensive network of partners nationwide with capacity for single-piece, small and medium series machining.

04

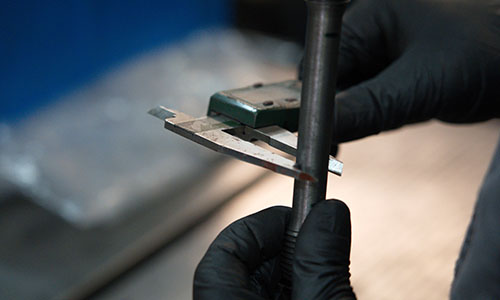

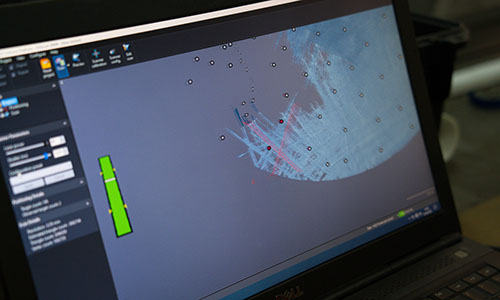

QUALITY CONTROL

DURITCAST is equipped with means of control for both the process and the product. The technicians are constantly certified and trained to be able to analyze all types of parts

Process Control

b) Sand control; conventional sand control equipment (permeability, humidity, strength, compatibility, active clay...)

Product control

b) Destructive: mechanical tests; metallographic tests