PROCESS

DEVELOPMENT AND DESIGN IN PARTNERSHIP FOR SUPERIOR RESULTS

PRODUCTION

DURITCAST has the expertise and professionalism to develop the iron alloy that suits the customer's product and to manufacture the most complex parts up to 5000kg.

MOULDING

2

MOULDING LINES

WITH A

PRODUCTION

CAPACITY

OF

BETWEEN 5KG AND 5000KG

We carry out strict quality control to ensure the consistency of the mixtures of the components used, both in green sand and in self-drying sand. Thus, ensuring the quality necessary for the production of parts for all types of industries.

MACHARY

3

CORE

SHOOTING

MACHINES

WITH

CAPACITY

BETWEEN 6,5L AND 25L

The sand core production is performed taking in consideration all drawing specifications for the parts inner shape.

FUSION

4

FURNACES

WITH

IRON MELTING

CAPACITY

BETWEEN 1000KG AND 4000KG

We guarantee strict control throughout the melting process, to obtain all the chemical and thermal properties necessary to ensure compliance with the standards and technical specifications of each project.

MANUAL DEBURRING

15

CABINS

FOR DEBURRING

PARTS

BETWEEN 5KG AND 5000KG

During this stage, we remove burrs and imperfections that originate from the molding process.

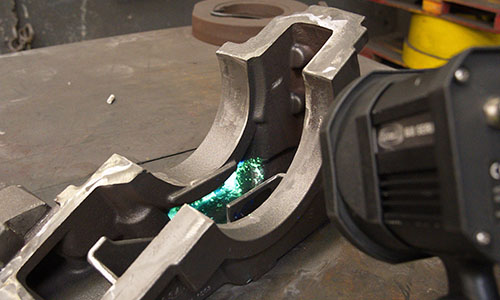

AUTOMATIC DEBURRING

3

ROBOTIC CELLS

FOR

DEBURRING

PARTS

BETWEEN 5KG AND 500 KG WITH OR WITHOUT JIGS

Our robotised cells allow products with higher dimensional requirements to be delivered quickly and efficiently.

GRINDING

3

PARTS SHOT

BLASTING

BOOTHS WITH TWO

SURFACE FINISH

LEVELS

BETWEEN 5KG AND 2000KG

The shot blasting operation allows, in a first stage, to clean the parts from sand and oxides from the molding and pouring process, and in a 2nd stage, to perform a surface finish after the deburring process.

SERVICES

HEAT TREATMENTS

We perform heat treatments according to customer specifications and needs:

- Normalizing;

- Stress relief;

- Annealing.

MACHINERY

We apply the same rigour and quality standards whether the project is a single piece or a small or large-scale series.

SURFACE TREATMENTS

The surface treatment solutions available increase the longevity and durability of castings. In order to combat wear and tear, which occurs through corrosion or oxidation, DURITCAST joins DURITCOATINGS with highly advantageous solutions, such as:

- High Speed Thermal Projection (Plasma, HVOF, EAWS)

- Physical Vapour Coatings (PVD, PA-CVD)

QUALITY IS THE RESULT OF AN EFFICIENT PROCESS

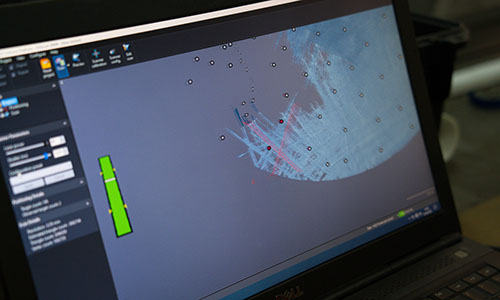

DURITCAST is equipped with means of control for both the process and the product. The process at DURITCAST is guaranteed with two control approaches, Process and Product.

The technical team is made up of highly competent professionals who are constantly trained and certified in order to guarantee precise and rigorous analysis and monitoring of any type of part.

PROCESS CONTROL

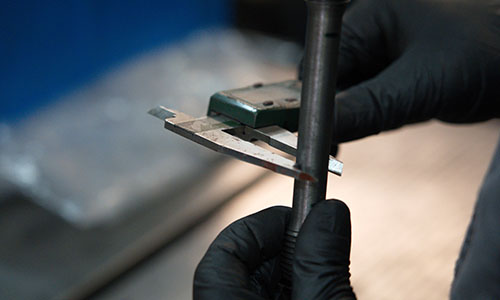

The means of process control are used throughout all stages of production and are safeguarded by the use of equipment that monitors the most relevant areas.

Metal control: Spectrometer, Thermal Analysis, LECO (C, S) (O, N), Optical Microscope, Pyrometers.

Sand Control: conventional control of permeability, humidity, resistance, compaction, active clay.

PRODUCT CONTROL

Product control, carried out in the final stages of production, guarantees the reliability that is intended to be achieved between the customer's requirements and the result obtained. In order to accurately safeguard this, we carry out the appropriate tests for each type of part.

Tests:

FIND OUT HOW WE CAN ADD VALUE TO YOUR BUSINESS!

Copyright © DURITCAST